For more than 20 years, GAT Gaertner Automobile Technology has been creating sophisticated components for the industrial, safety technology and motor sports sectors. Over the years we have become a reliable and respected partner and supplier in the industry, because we guarantee our customers a prompt response and the highest quality. We are able to do this because we have a well-functioning team, a flat organisational structure and excellent, experienced employees, who ensure orders are processed quickly without complications. Every day we are united by our common goal of keeping our customers happy and satisfied. Whether they provide us with CAD data or come to us with an idea in their head, we are equipped for every eventuality, producing their precision components on schedule or making their vision a reality.

The best examples of our ingenuity, our innovation and our diverse skills are reflected in the solutions we have developed in-house, particularly those for the motor sports sector, our prototypes and our special components.

If we’ve sparked your interest and you’d like to find out more, please get in touch or come and meet us in person.

We use two different CAD/CAM solutions to enable us to adapt perfectly to the task in hand and create the wildest contours cost-effectively. With the support of our in- house fixture construction department, no challenge is too difficult for us.

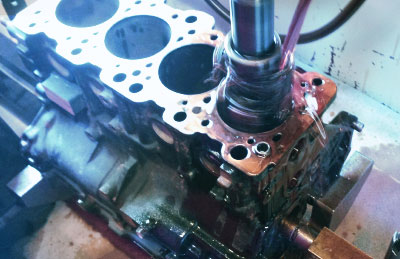

We are the specialists when it comes to turned and milled parts, whether it’s small runs of 5-50 parts or larger batches of up to 10,000 parts. Our more than 20 years of experience in this sector mean you are guaranteed the best possible results. With the latest machines and specially trained staff, we can help you tackle any challenge.

Flat-grinding (500 mm x 1000 mm) and honing in our production chain forms an integral part of our range of services. With four honing machines we precision- process inner bores from 3 mm to 350 mm diameter to the micrometre with a finish quality of Rz < 1.

In collaboration with reliable partners, GAT can also offer a wide range of surface coating and heat treatment processes. Whether it’s powder coating, anodising, TiN coating, burnishing or plasma nitriding, case hardening or inductive hardening, we can handle any conceivable surface.

To satisfy our customers’ high safety standards, we can carry out surface crack testing on request. We have a special in-house system that allows us to offer the flexibility required.

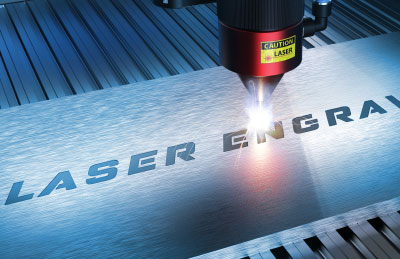

To ensure your products are traceable, we can add serial numbers, manufacturing dates, part numbers or barcodes to your parts on request.

Achieving success together – in friendly, straightforward partnership. This is what we stand for, what we are proud of and what we aim to demonstrate every day when we deal with our partners and customers. Because there’s nothing that brings people together more than a common goal and a shared passion – in our case, that’s a good end-product.

This was the vision Martin Gärtner had when he founded his company in 2002. Starting out on a small scale with just two employees and limited machinery, but more than enough motivation to make up for it, he created the first specialist components for the motor sports sector. Today, we can look back on almost 20 years of history, and yet it’s still early days. With our constantly growing team managing a wide array of machinery, every day we are glad to be a part of this company.

Quality is paramount when it comes to our services.

In order to guarantee this, we have an in-house measuring equipment department,

which is not only equipped with the best 3D measuring technology, but also inspects

and monitors the measuring equipment at each individual workstation on an ongoing

basis.

As a result, you benefit from on-schedule deliveries, simplified incoming goods

inspection and a perfect price-performance ratio thanks to a minimal error rate.

Certificate Din ISO 9001-2015 (PDF 224 KB)

We are a highly specialized family company that offers its employees a modern environment based on trust. In a 3-shift operation, we manufacture a wide range of parts on modern CNC machining centers of the latest generation. The degree of automation extends to unmanned robot loading. We are valued by customers around the world for the high quality we deliver and for our vast experience in manufacturing unique parts that few others can.

Working at GAT Industries, learn more hereManaging Director

m.gaertner@gat-industries.com